Home > Parts Washers > Rotary Parts Washers > Turntable Parts Washers

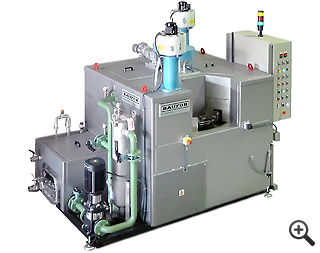

Turntable Parts Washers

- Continuous parts cleaning and drying

- One or two stages versions

- Parts transported on a turntable

- Loading and unloading from the same point

- Manual or robotic loading and unloading

- Precision cleanig if the parts so required

- Designed and built to measure

- Easy access for maintenance

- Built in steel or AISI-304 stainless steel

- Steam, gas, diesel and electric heating

General description of turntable parts washers

BAUFOR's Rotary parts washers clean/degrease and dry metal or plastic parts as a continuous cycle.

The parts are transported on an adjustable speed turntable, and if because of the part characteristics precision cleaning is required, the turntable will perform precise stops in order to guarantee effective degreasing. Parts are loaded and unloaded from the front of the washer, a process which may be performed manually or robotically.

Parts cleaning, degreasing and drying

BAUFOR's turntable parts washers can perform the process in several stages: washing (calibrated if the parts so require), blowing to remove water from holes and cavities, and drying by hot air.

The water can be heated electrically, by gas, diesel or steam.

Rotary parts washers can be fitted with filters in the pressure pump to improve filtering and eliminate particles from recirculation.

The mist collectors remove humidity from inside the machine, facilitating drying and preventing mist clouds from forming in the loading zone.

Parts transported on a turntable

The parts are transported on a turntable designed on the basis of the characteristics of the parts to be washed and the production volume.

As the platform on which the parts are supported turns on an axle, loading and unloading takes place at the same point, while preventing any parts from falling in the event of a lack of care on the part of the operative. The parts can be placed directly on the turntable if their position is not important, or otherwise on special anchoring points or supports if their complexity requires precision cleaning and/or blowing.

If only one type of part is to be washed and the parts are relatively complex, special supports will be employed.

If more than one type of part is to be degreased and the parts require precision cleaning, anchoring points will be employed.

Accessibility

BAUFOR's aqueous turntable parts washers offer substantial benefits in terms of maintenance and cleaning tasks.

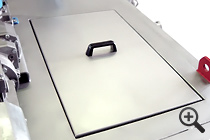

The different treatment zones are fitted with access covers at the top. The washing tank also has a top cover and cleaning hatch, and if there is a lower zone this will have a side hatch and a top access cover.

All the parts washer elements are easily accessible and removable: Nozzles, collectors and washing branches. Blower nozzles and pipelines. Drying nozzles. Cowling protecting the motor system and front panel accessing the turntable axle.

To clean or change the washing nozzles one need only remove the top cover to gain access inside the chamber.

If the rotary washer is fitted with a blower zone, a side inspection hatch will be fitted to access the pipelines and nozzles.

Standard features

Stainless steel chip-baskets

After the solution has been sprayed onto the parts, it all then passes through the strainer basket to eliminate any small solid particles from the circuit and prevent them from being fed into the pump. Accessible via the tank lid and easy to clean.

Low solution level shut-off and automatic water fill

The inductive detector maintains the level in each tank between set parameters by operating the pneumatic electrical valve to automatically refill with water. This guarantees that the level covers the heat elements at all times.

Bomba vertical

BAUFOR's rotary parts washers are fitted with submersible vertical pumps equipped with a filter to prevent any object which may have accidentally fallen into the tank from being sucked in.

Heat and sound insulation

All our parts washers are heat-insulated as standard to reduce heat loss and thus save energy. This heat insulation prevents the outer surfaces from reaching high temperatures. The same insulation also reduces the machine's sound level, keeping this within the legal noise parameters.

Exhaust fan

The exhaust fan extracts the humidity-laden air from inside the parts washer, helping the parts dry and preventing the formation of mist clouds in the loading and unloading zone. A chimney leading outside must be fitted.

Drying ventilator

The drying fan ensures that the air in the drying chamber constantly circulates. The air is drawn across the heating elements and pumped to the drying nozzles, which in turn direct the hot air onto the parts.

Motor/gearbox/variator unit

This is responsible for rotating the turntable and allows its speed to be adjusted. At the axle connection a clutch is fitted to protect against excess strain such as overloading or snagging due to poor loading of parts.

Miscellaneous

Pressure control gauges and valves. Reinforced tank heating elements. Emergency shut-offs in the loading/unloading zone and control panel. Digital temperature controllers. Drainage valves. Anti-vibration feet. Synthetic rubber curtains or silhouettes with the profile of the parts to clean.

Optional accessories

Oil Mist Collectors

The mist collector eliminates suspended oil from the degreasing solution, using the continuously rotating disc. Fitted in the tank alongside the deposit to avoid any turbulence caused by the pump. Lengthens the lifespan of the degreasing mixture.

BAUFOR oil coalescer

The best method for eliminating large quantities of oil. In a separate tank fitted with a screw pump to prevent mixture and guarantee the oil is eliminated. Considerably lengthens the lifespan of the aqueous solution.

Wheel type oil skimmer

This eliminates suspended oil from the degreasing solution, using the continuously rotating disc. Fitted in the tank alongside the deposit to avoid any turbulence caused by the pump. Lengthens the lifespan of the wash solution.

Emptying tank

Facilitates maintenance tasks such as cleaning of the washing tank base. Emptying can be performed manually or automatically. Fitted with induction level detector and pump.

Filtering systems

Our rotary parts washing systems can have different types of filter fitted. Single or multiple bag, cartridge or basket filters. Fitted with a "filter dirty" alert indicator.

Automatic detergent dosing

Injects the desired percentage of cleaning product into the water. It works by volumetric proportion, guaranteeing the mixture percentage irrespective of any change in pressure or flow rate.

Automatic device and operator panel

Automation of working and control processes by means of a control panel with touchscreen. Manual mode, automatic mode, component testing, temperature indicators, heating element programming, etc.

Programmable heating timer

BAUFOR's turntable parts washers need to reach an optimum temperature in order to work effectively. The programmer can be used to plan the start-up of the elements prior to working hours seven days a week.

Any component the client may wish

BAUFOR industrial parts washers stand out because they are designed to measure. Any component which the client may wish can therefore be fitted to the parts washer.

- HYDRORESA, S.L.

- C/ Fogars de Tordera 65

- 08916 Badalona (Barcelona)

- +34 932 327 217

- +34 932 314 971

- baufor@baufor.com