Home > Parts Washers > Special Parts Washers

Special Industrial Parts Washers

If the three types of parts washer established as standard (pass-through washers, rotary parts washers or cabinet washers) do not meet the client's needs, we design and manufacture special industrial parts washers.

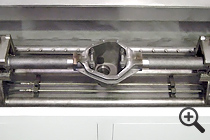

Special Parts Washer for Axle Housings

Special parts washer for the cleaning, blowing and drying outside and inside of axle housings.

Front loading and unloading and fully automatic intermittent cycle. The axle housings are positioned on a special device with automatic clamps and mobile lances to wash and blow inside.

Industrial parts washer fitted with a backup compressed air tank to guarantee supply, central hydraulic unit to move the cylinders and the rotary motor, drying ventilator, centrifugal separator and bi-manual control.

Special Parts Washer for Large Transformers

BAUFOR special cabinet parts washer with opposing doors, for the washing and drying of large-sized, heavy electric transformers.

Parts loaded and unloaded on opposite sides. Fully automatic cycle with motorised step-by-step roller transportation system and automated vertically opening doors.

Parts washer fitted with mist aspirator, oil separator, proportional detergent doser and side hatches for internal maintenance. Manufactured in AISI 304 stainless steel.

Loading and unloading are performed by means of the corresponding hoppers located on opposing sides of the parts washer.

Special Burner Installation, Crack Control

Special BAUFOR installation for sporadic control of gearbox components to ensure their proper manufacture.

Treatment tanks in a fully cowled section with an automatic working cycle using a motion gantry. Tanks made from stainless steel or plastic depending on the treatment.

Aspiration of fumes and mist, water inlet and fully automatic refilling and joint emptying collector. Fitted with a control system and fire-fighting for any tanks requiring this.

- HYDRORESA, S.L.

- C/ Fogars de Tordera 65

- 08916 Badalona (Barcelona)

- +34 932 327 217

- +34 932 314 971

- baufor@baufor.com