Home > Parts Washers > Cabinet Parts Washers > Rotary Basket Parts Washers

Rotary Basket Parts Washers

- Industrial washing/degreasing of any type of part

- Appropriate for low production levels

- Positioning on the rotary basket

- Top load parts washer

- Automatic washing cycle

- Space, power and low cost

- Designed and built to measure

- Solid and compact

- Built in steel or AISI-304 stainless steel

- Heated or unheated versions

General description of rotary basket washers

BAUFOR's spray wash cabinets can wash metal parts in just a few minutes, with the parts loaded and unloaded via the top. Parts are washed and degreased by spraying at 3 bar.

A turntable fitted with a basket guarantees that the parts will be washed on all sides, avoiding any blind spots. Automatic cleaning and mist aspiration cycle. The top cover can be opened manually or automatically.

2 different versions of rotary basket parts washers are supplied: Heated, for the use of alkaline products, or unheated for the use of cold products.

Industrial washing and degreasing of all types of parts

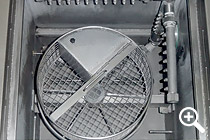

The rotary motion of the basket is generated by the force of the water spray, without the need for a motor, thereby saving energy. When the washing cycle ends the exhaust fan removes any mist from inside the washing cabinet, preventing this from emerging when the lid is opened and assisting in the partial drying of the parts thanks to the latent heat which they have acquired and the entry of fresh air from outside.

The rotary motion of the basket, the distribution of the pipelines and the cleaning solution sprayed at 3 bar guarantee optimum washing of the parts on every side.

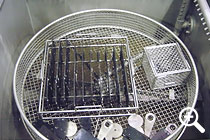

Positioning of the parts on the rotary basket

The parts are loaded onto a basket which is tailored to the parts to be washed.

The basket can be loaded with different types of parts and, depending on their characteristics, they can be placed directly on to the basket, onto tools, special supports or into different compartments designed in accordance with their needs.

Accessibility

Maintenance tasks are extremely simple to perform on rotary basket parts washers given their small size and the limited number of elements, which are easily accessible.

The pipelines and nozzles can be removed. The cleaning hatch allows the base of the machine to be cleaned.

Standard features

Low solution level shut-off and automatic water fill

The float detector maintains the level in each tank between set parameters by operating the pneumatic electrical valve to automatically refill with water. This guarantees that the level covers the heating system at all times.

Horizontal pump

BAUFOR's cabinet parts washers with rotary basket are fitted with an external horizontal pump equipped with a filter to prevent any object which may accidentally fall inside from being sucked in.

Heat and sound insulation

All BAUFOR parts washers are heat-insulated as standard to reduce heat loss and thus save energy. As they are heat-insulated, the outer surfaces do not reach high temperatures, while the noise levels generated by the parts washer remain within the legal standards.

Exhaust fan

The exhaust fan removes mist from inside the cabinet parts washer, preventing this from emerging when the top cover is opened, and helping the parts to partially dry. Once the machine has been installed, it will need a chimney leading to the outside to be fitted.

Door sensor and electromagnetic closure

In order to ensure that the cycle begins with the cover closed and to prevent it from being opened during the washing process, our rotary basket parts washers are fitted with a door sensor and electromagnetic closure.

Miscellaneous

Pressure control gauge and valve. Reinforced tank heating elements. Emergency shut-off in the control panel. Digital temperature controllers. Drainage valves. Anti-vibration feet. Pump aspiration filter. Modular programmable automatic device with operator panel to modify the cycle times.

- HYDRORESA, S.L.

- C/ Fogars de Tordera 65

- 08916 Badalona (Barcelona)

- +34 932 327 217

- +34 932 314 971

- baufor@baufor.com